sheet metal drawing standards

The first two letters the discipline designators identify the construction discipline. But what makes these guidelines so beneficial to customers like you.

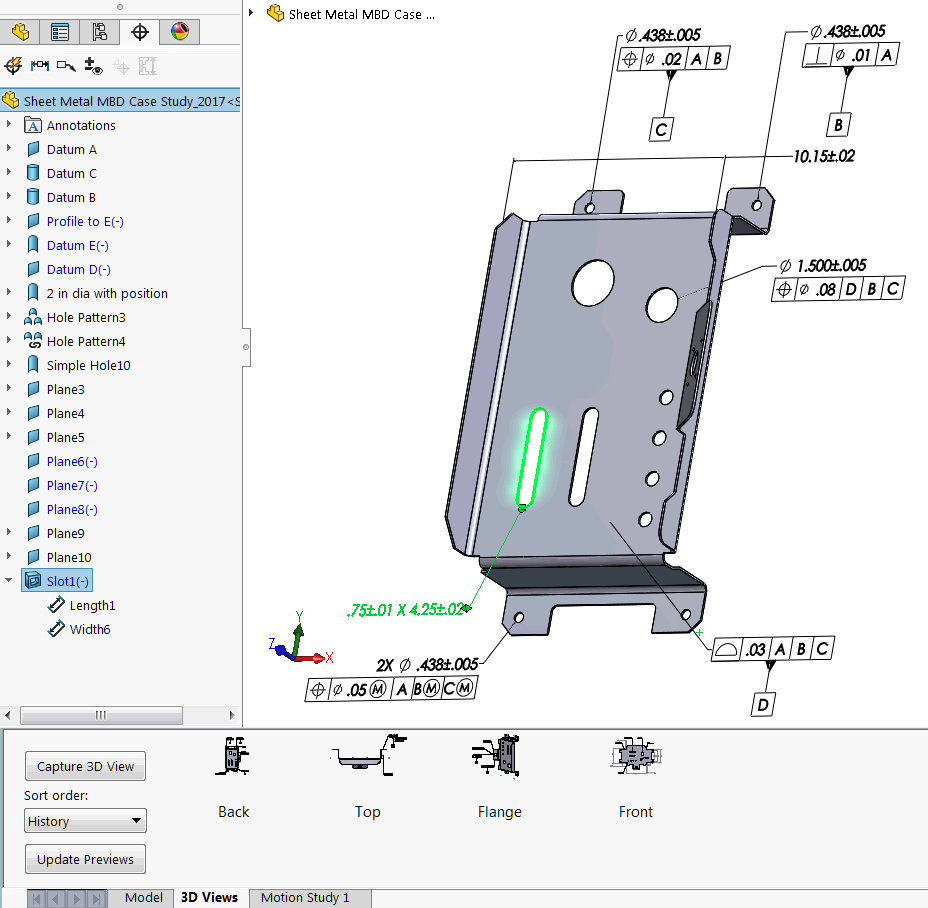

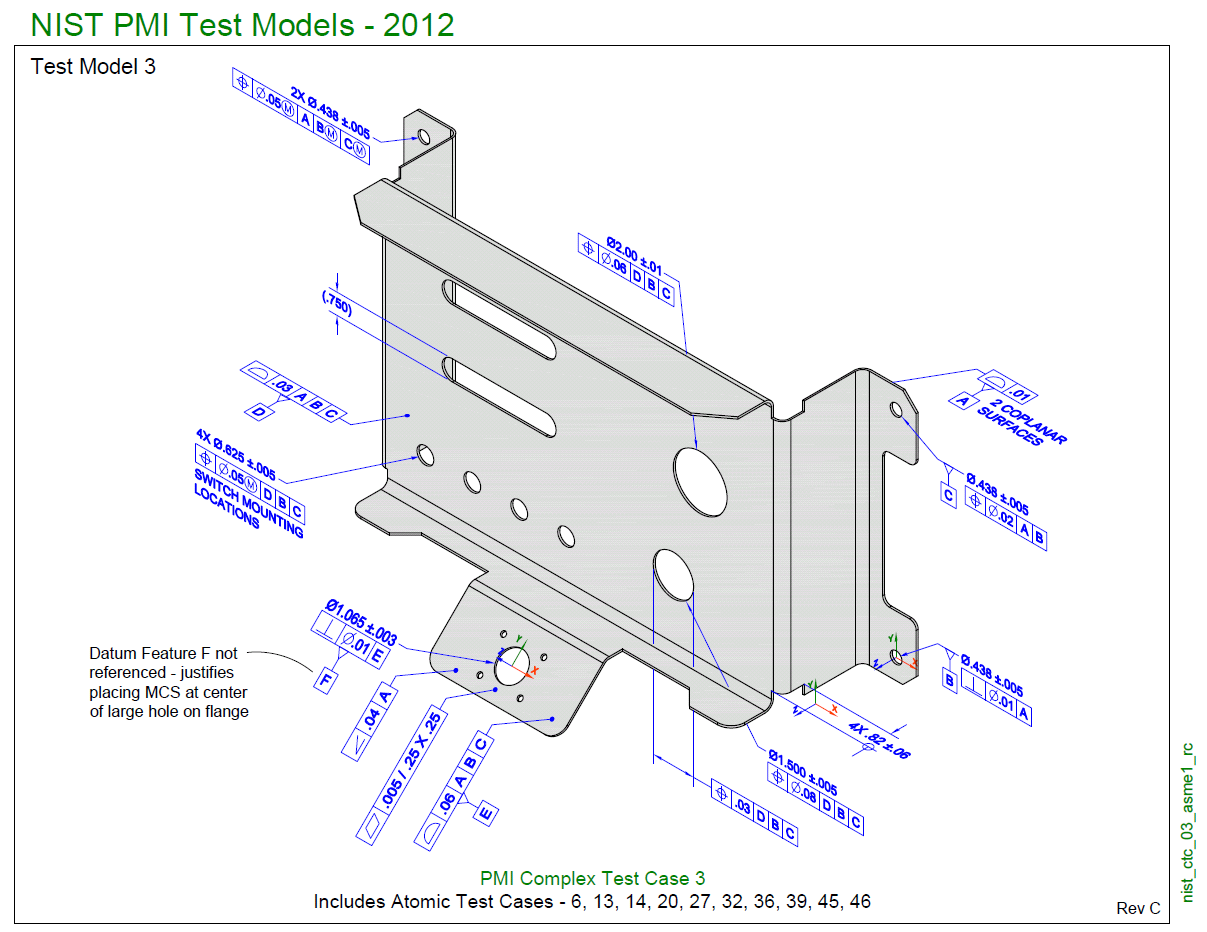

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

Standard in which case AS SHOWN should be noted on the drawing.

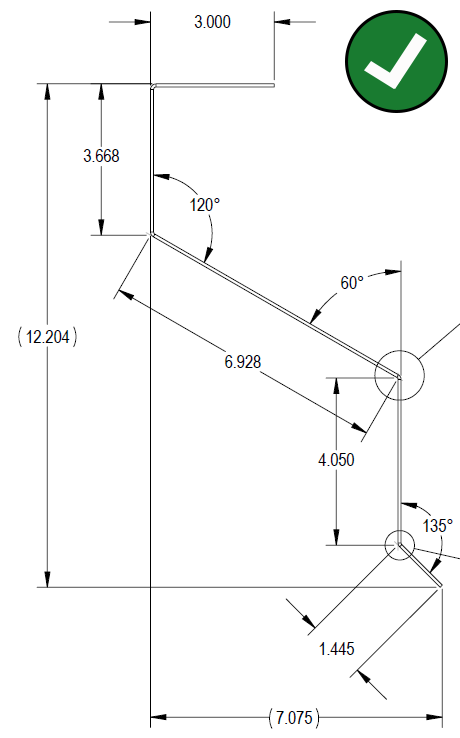

. Engineering drawing abbreviations and symbols are used to communicate and detail the characteristics of an engineering drawing. Offsets should follow the same sheet metal design guidelines as other bends. It reviews general dimension standards as well as requirements for.

I am not aware of standards for them separate from any other kind of fabrication drawing. Depending on the quantity of zinc in the alloy. 215 On detail drawings with 3 or.

They should be legible and clear especially numbers as they often have to be read on their own. The variation becomes larger as the bend angle increases. All drawings require some form of lettering and numbers.

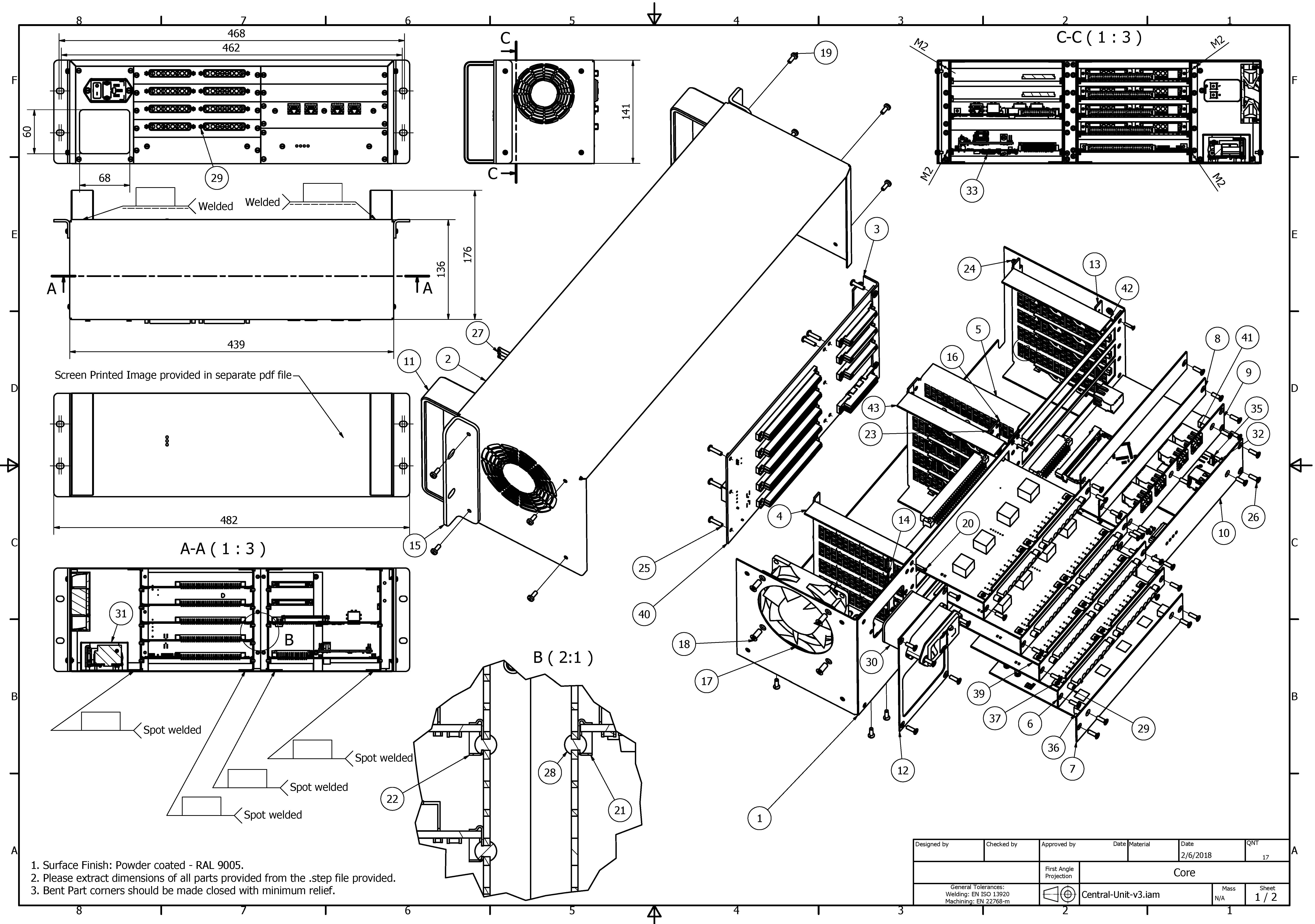

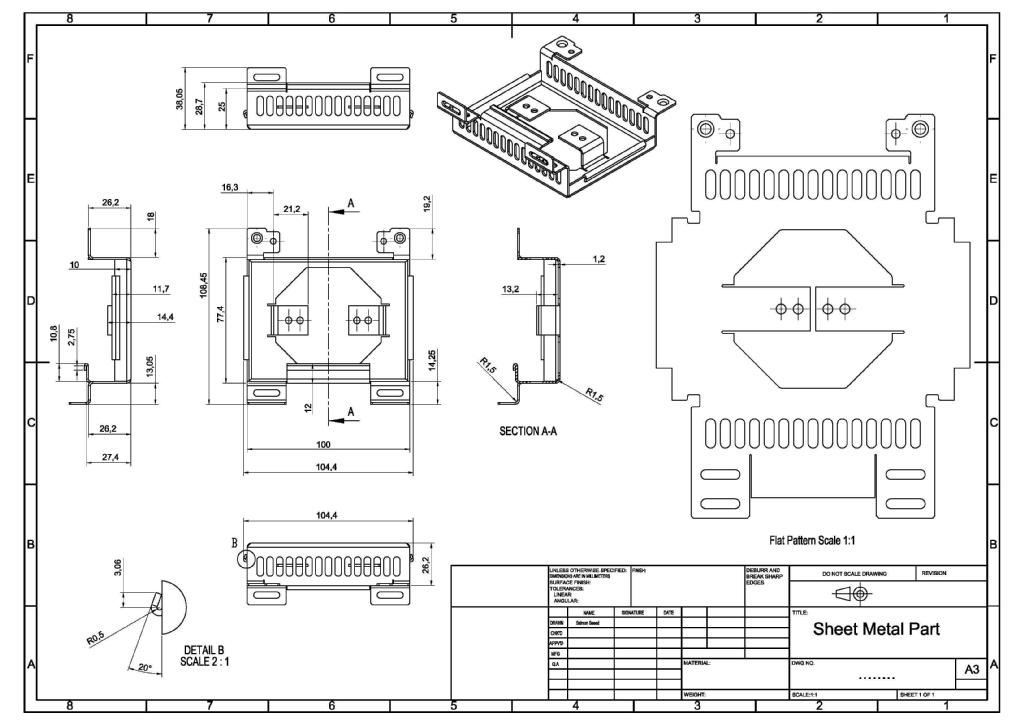

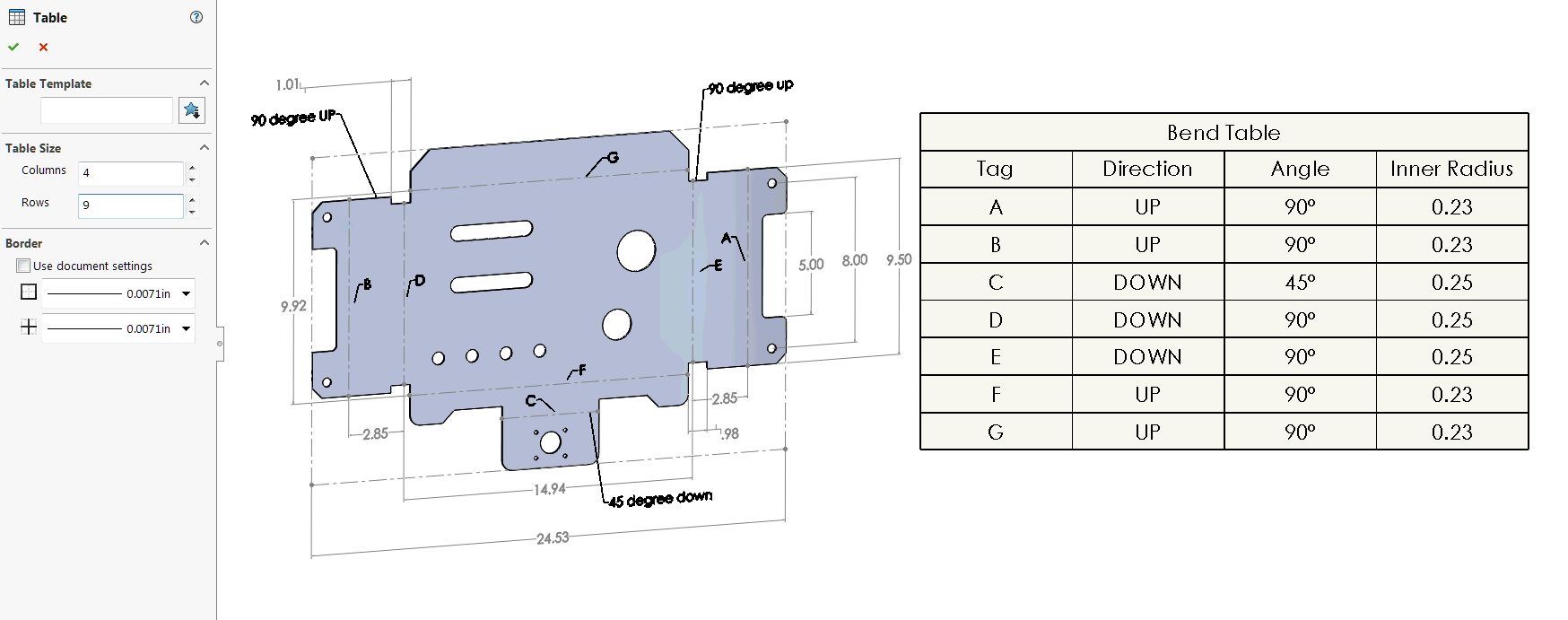

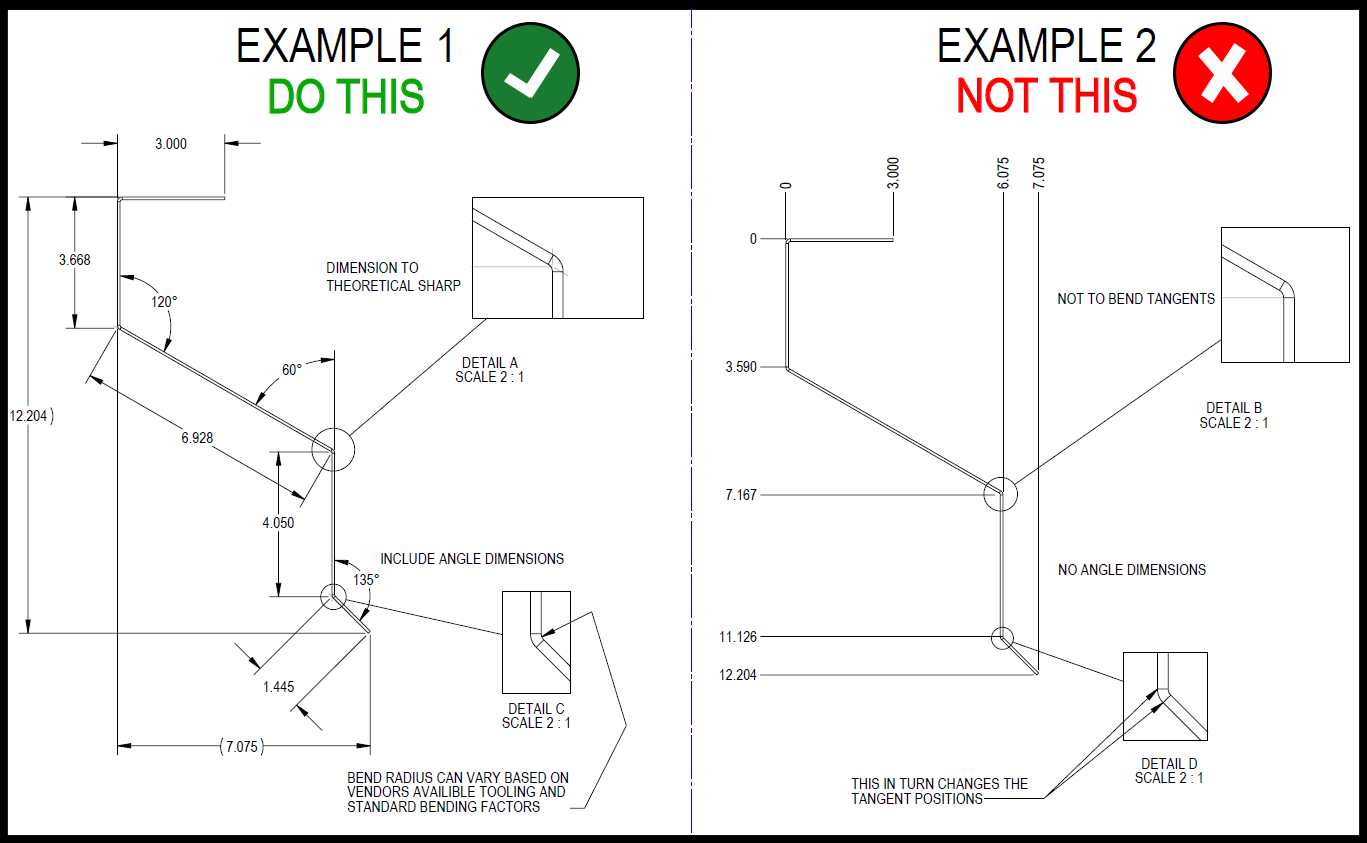

This video demonstrates how to properly dimension a sheet metal layout technical drawing. There are three components that make up sheet numbers in a set of construction documents. Workmanship Standards 3 1 Purpose The purpose of this specification is to define standard quality workmanship requirements for sheet metal.

Above 24 inches practice varies but in general feet and inches are used as 3-2½ for 3 feet 2½ inches. A description is not available for this item. This gives brass sheet a wider range of performance depending on end use of the designed part.

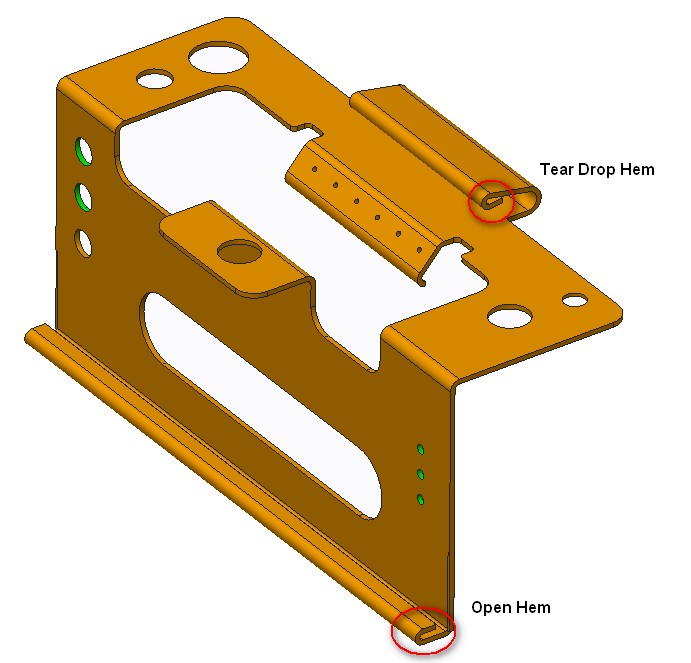

214 All tapped holes are assumed to have coarse threads unless otherwise specified. Sheet metal is one of the shapes and forms metal can be bought in. The minimum recommended sheet metal flange bend length avoid cracks in the bending area.

Electrical and Electronics Drawings March 2008 23. Lower-left corner of the drawing sheet touching the left and bottom border lines 3. Defining the Sheet Metal Parameters This task shows you how to configure the sheet metal parameters.

Drawing upon the considerable experience of its own CADD Task Force. I do lots of sheet metal drawings. SCS articulates the CAD standards that will enable SMACNA members and the rest of the AEC community to apply CAD.

2015 and AS 9102. Many sheet metal workers are educated and certified in two popular standards --ISO 9001. This list includes abbreviations common to the.

The principles to remember are. Upper-left corner of the drawing sheet touching the top and left border lines 2. Form height to thickness ratio To determine the minimum form height for sheet metal use the following formula.

D 25T R see below The height can be less but it required secondary. Packaging Drawings Not Available 21. We typically use C2680 for sheet.

Asme Sheet Metal Standards Briefly Discuss How The Term Precision Sheet Metal. Vertical figures about ⅛ in. Sheet metal drawing standards.

January 1 2020 - GMNA. The radius of an inside bend should be at least equivalent to the materials thickness to avoid. The Sheet Metal Parameters dialog box.

It shall be equal to three times of sheet thickness plus bend radius. Above the title block touching. Sheet Metal March 2008 22.

10 Pack 6 X 1 Hex Washer Head Self Drilling Screws Zinc. The basic sheet metal fabrication techniques include cutting bending punching stamping welding and finishing. Generally capabilities of of 09mm 20mm in thickness are able to be manufactured from sheet 3mm but this tolerance depends mainly on the.

Drawing Change Procedure March 2008 24. Sheet metal is any metal that has a thickness in between 056 millimetres. Sheet metal material selection is an iterative process.

There are other measurement. We will dive into the details of these techniques shortly. Click the Sheet Metal Parameters icon.

9981870 - Drawing Compounds Water Based for Sheet Metal. However once you expand over all four bends that number increases to a difference of 130 on the overall flat length of the part. Copper an alloy of copper and zinc brass is very ductile and corrosion resistant.

Minimum Sheet Metal Flange. High are usually used for dimensions. Sheet metal shops can bend to tolerances of 015.

York Haven Fabricators Inc.

Dimensioning For Ease Of Manufacturing

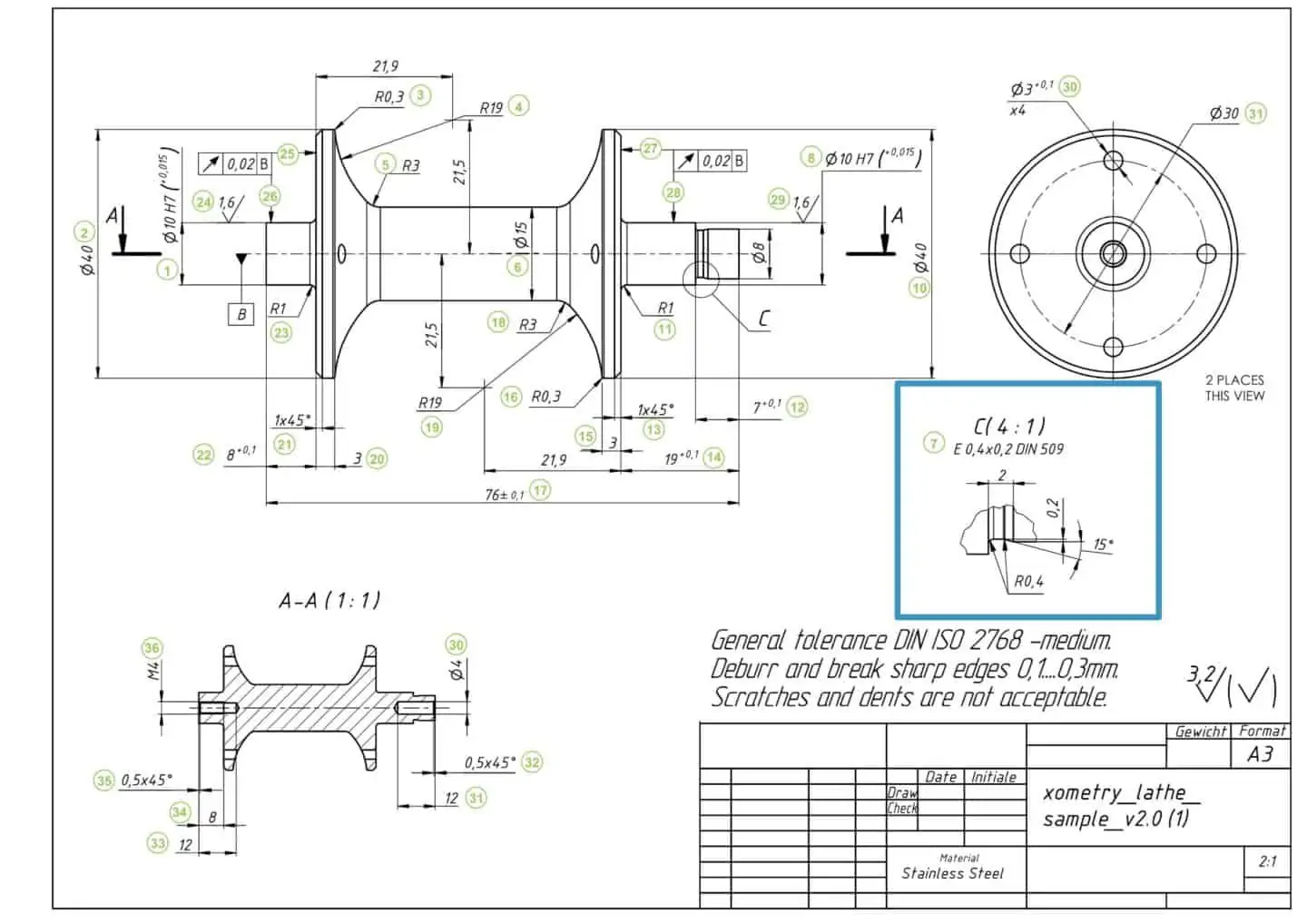

How To Prepare A Perfect Technical Drawing Xometry Europe

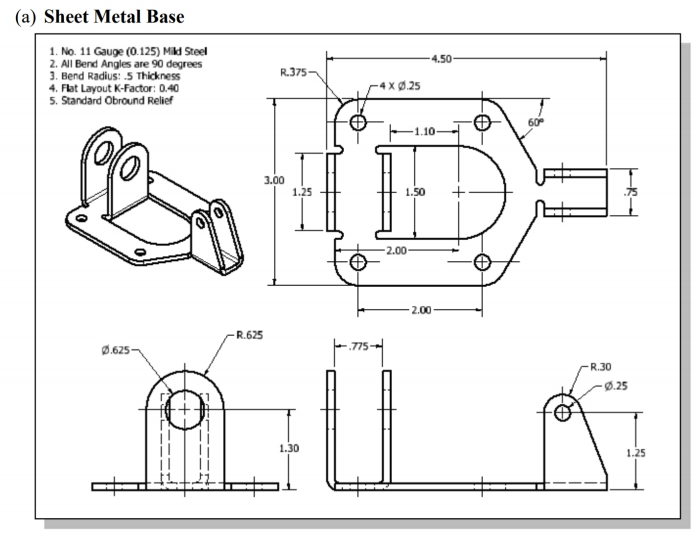

Solved A Sheet Metal Base 4 50 1 No 11 Gauge 0 125 Chegg Com

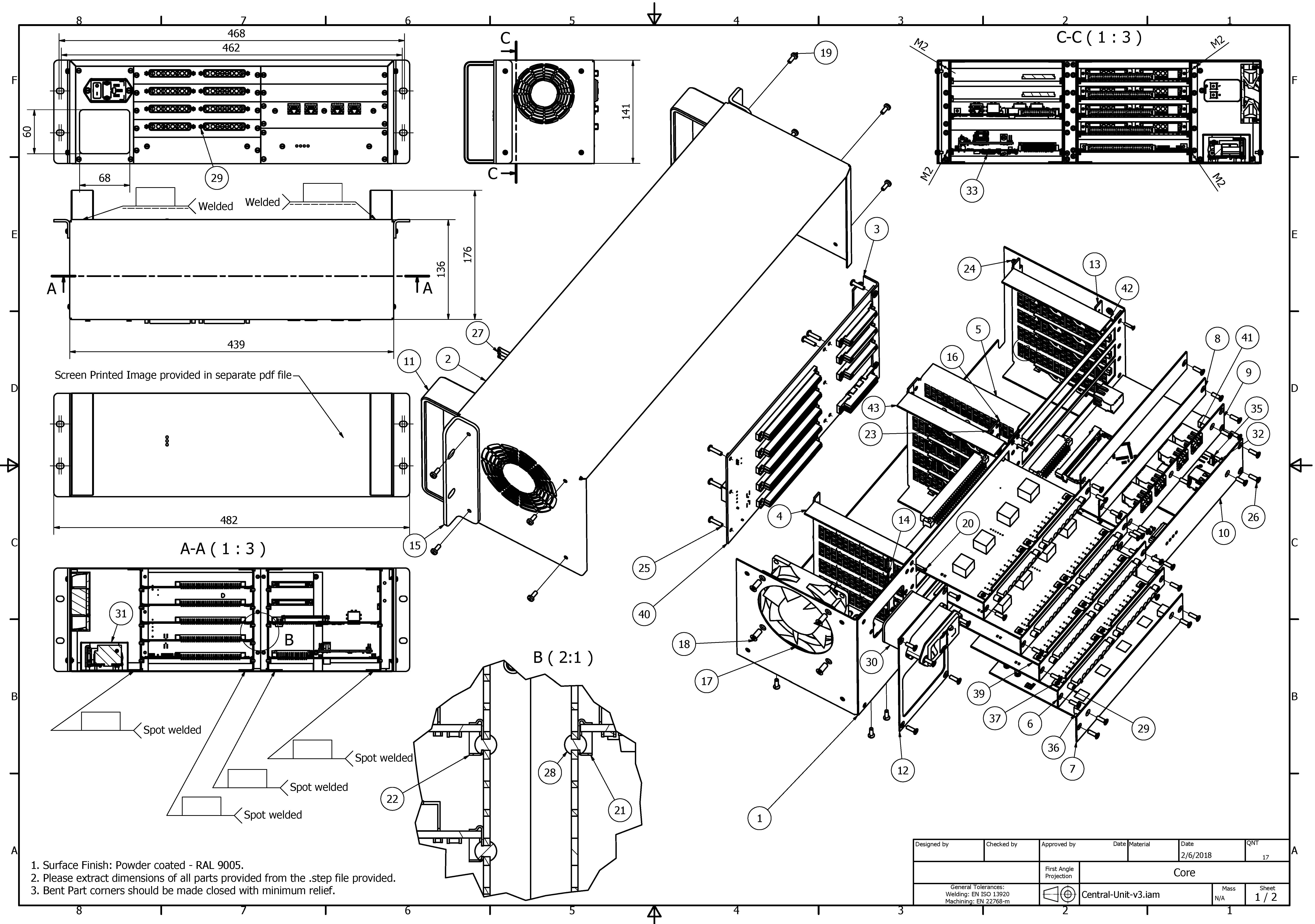

Freelance Sheet Metal Design Services For Companies Cad Crowd

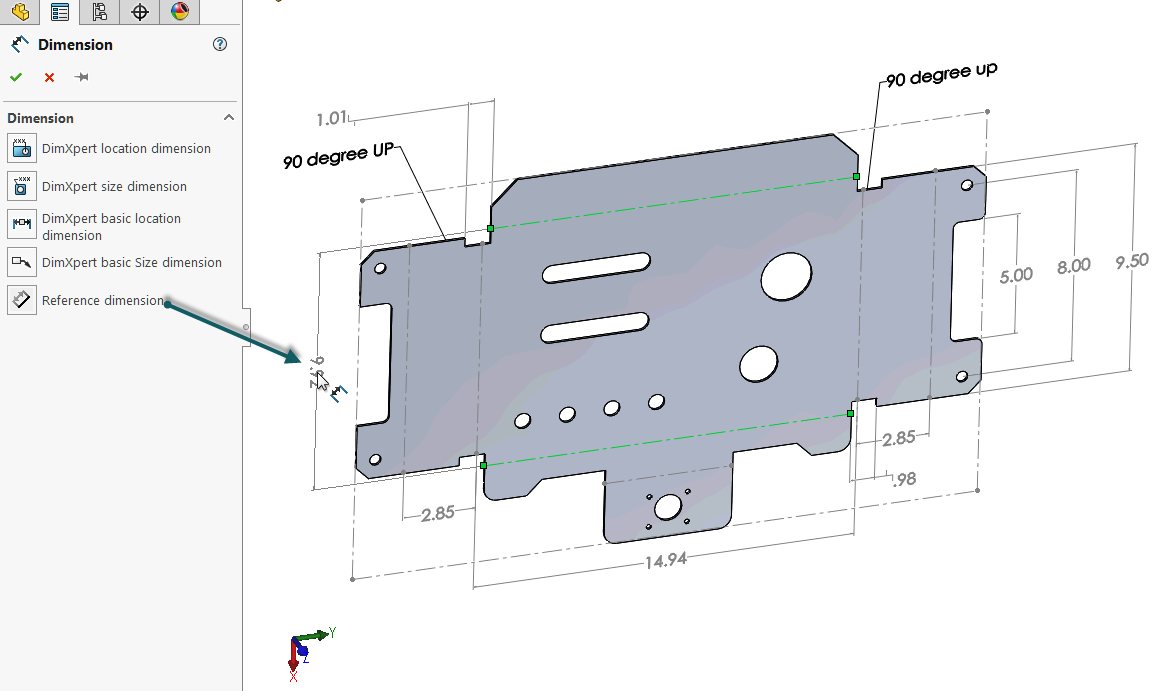

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

Freelance Sheet Metal Design Services For Companies Cad Crowd

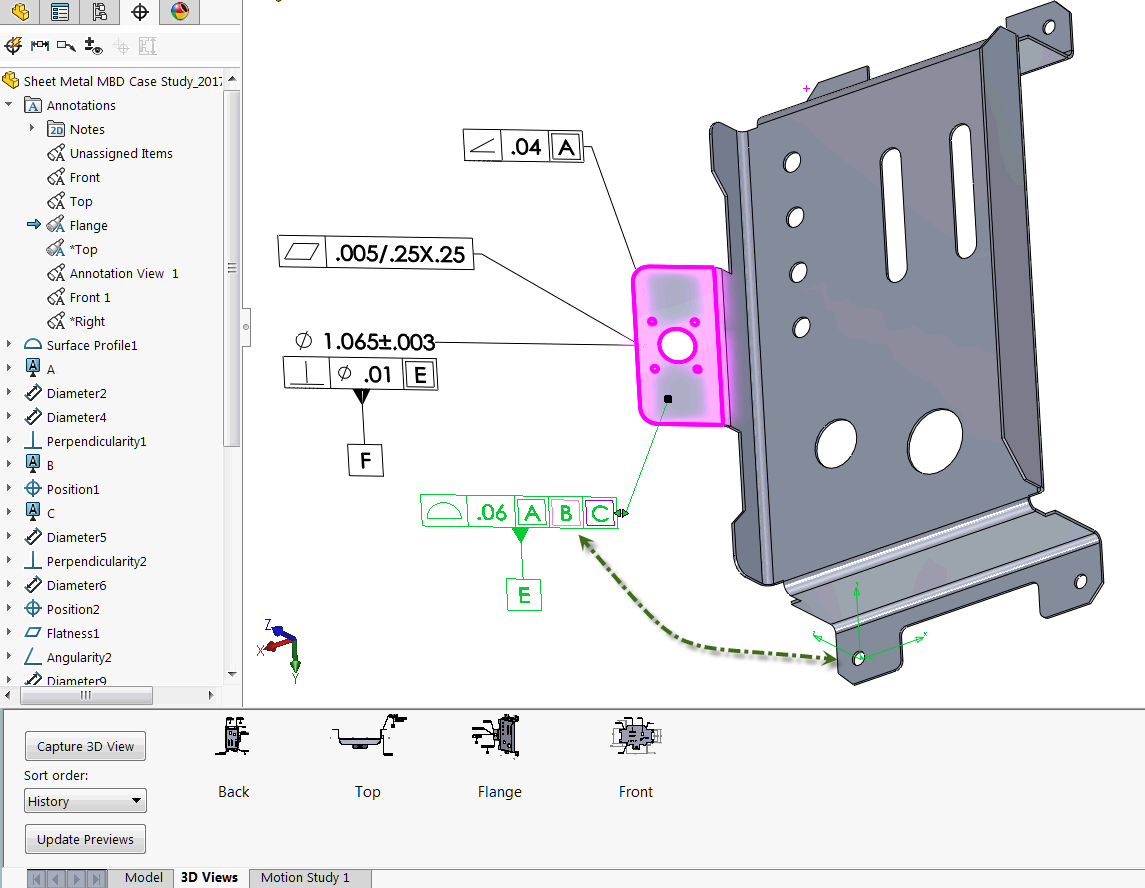

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

Sheet Metal Design Guidelines Dfmpro

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

Sheet Metal Dimensional Drawing Example Vista Industrial Products Inc

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

Sheet Metal Dimensional Drawing Example Vista Industrial Products Inc

Sheet Metal Drafting Chapter 3 Wikisource The Free Online Library

How To Present The Mbd Data Of Sheet Metal Parts Engineers Rule

Sheet Metal Dimensional Drawing Example Vista Industrial Products Inc

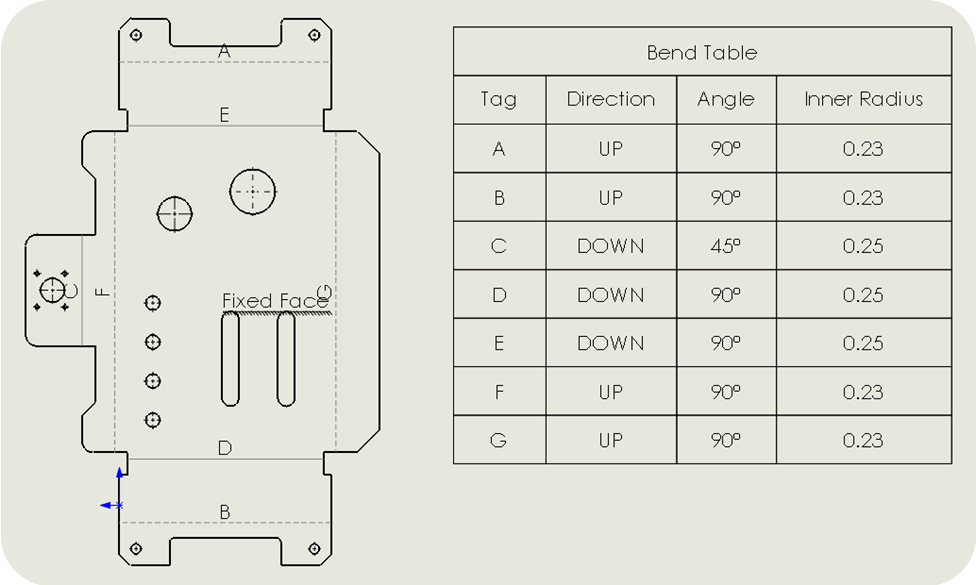

Solidworks Sheet Metal Drawing Tutorial Bend Line Flat Pattern Unfolded Bend Table Punch Table Youtube

Dimensioning For Ease Of Manufacturing

How To Prepare Drawings For Your Sheet Metal Supplier Komaspec